These days high alumina ceramic has become one of the most efficient wear material for many high abrasion applications. In XTWS we are always developing better materials mixing properties like rubber with ceramic parts.

We have also develop ceramic blocks for different areas where this type of work is need it.

The high alumina ceramic is commune used in the 92% alumina status but we have develop 95 and 99% of alumina in our ceramics giving a great abrasion advantage.

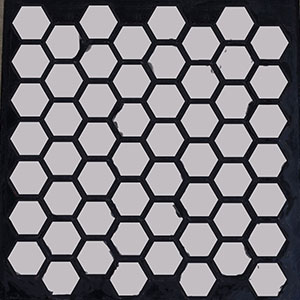

We have also develop blocks, cylinders and hexagonal ceramic different sizes and thicknesses make as required by our customers.

Have develop 95 and 99% of alumina and zirconia with full control of production in our ceramics giving great abrasion advantages.

Commonly know as Abrasion resistant steel, impact resistant steel, or high manganese casting products, this materials are the option for high impact areas within abrasion critical wear problems, were our goal is to design and fabricate the best cost efficient wear part for our customer.